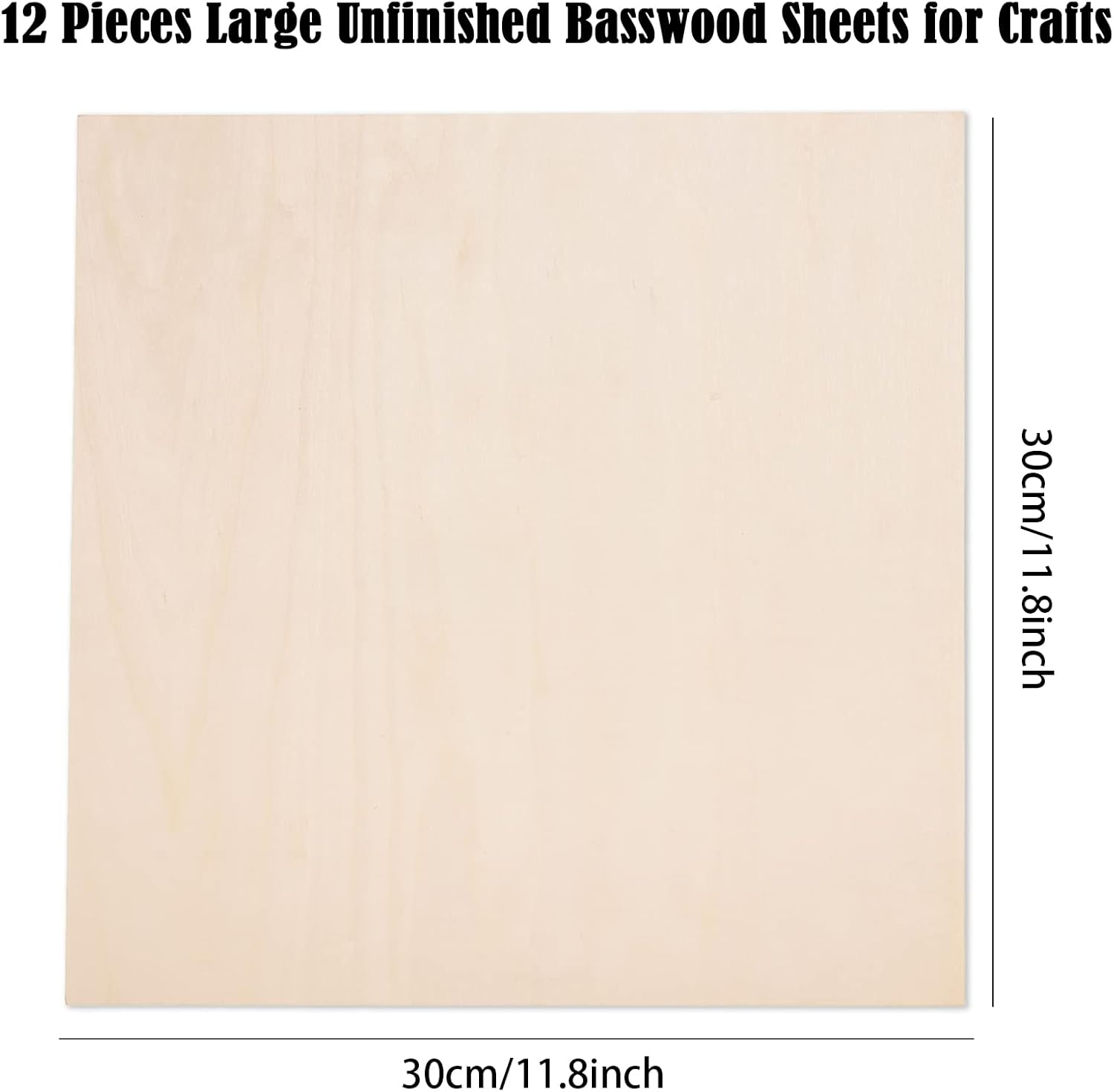

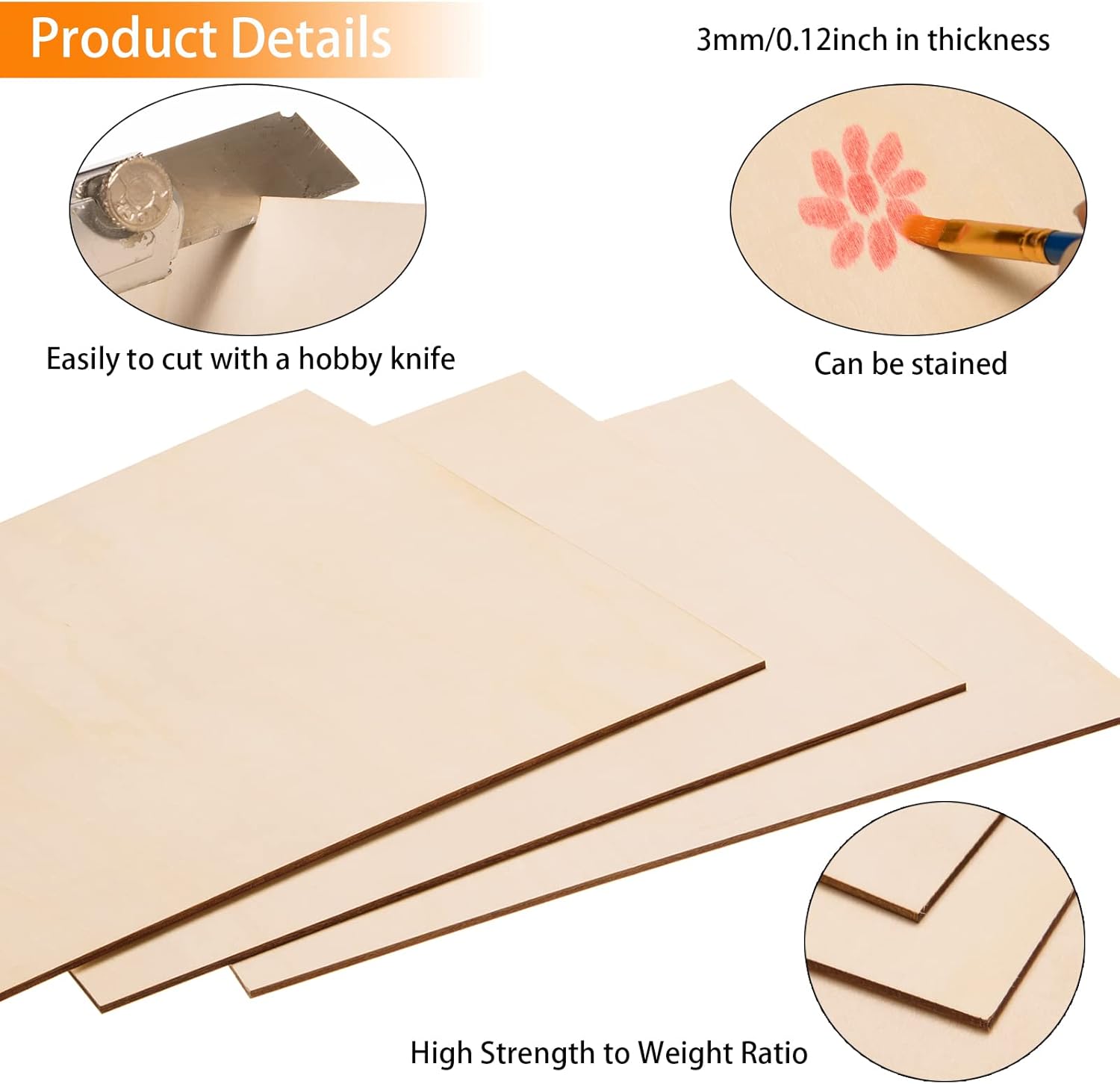

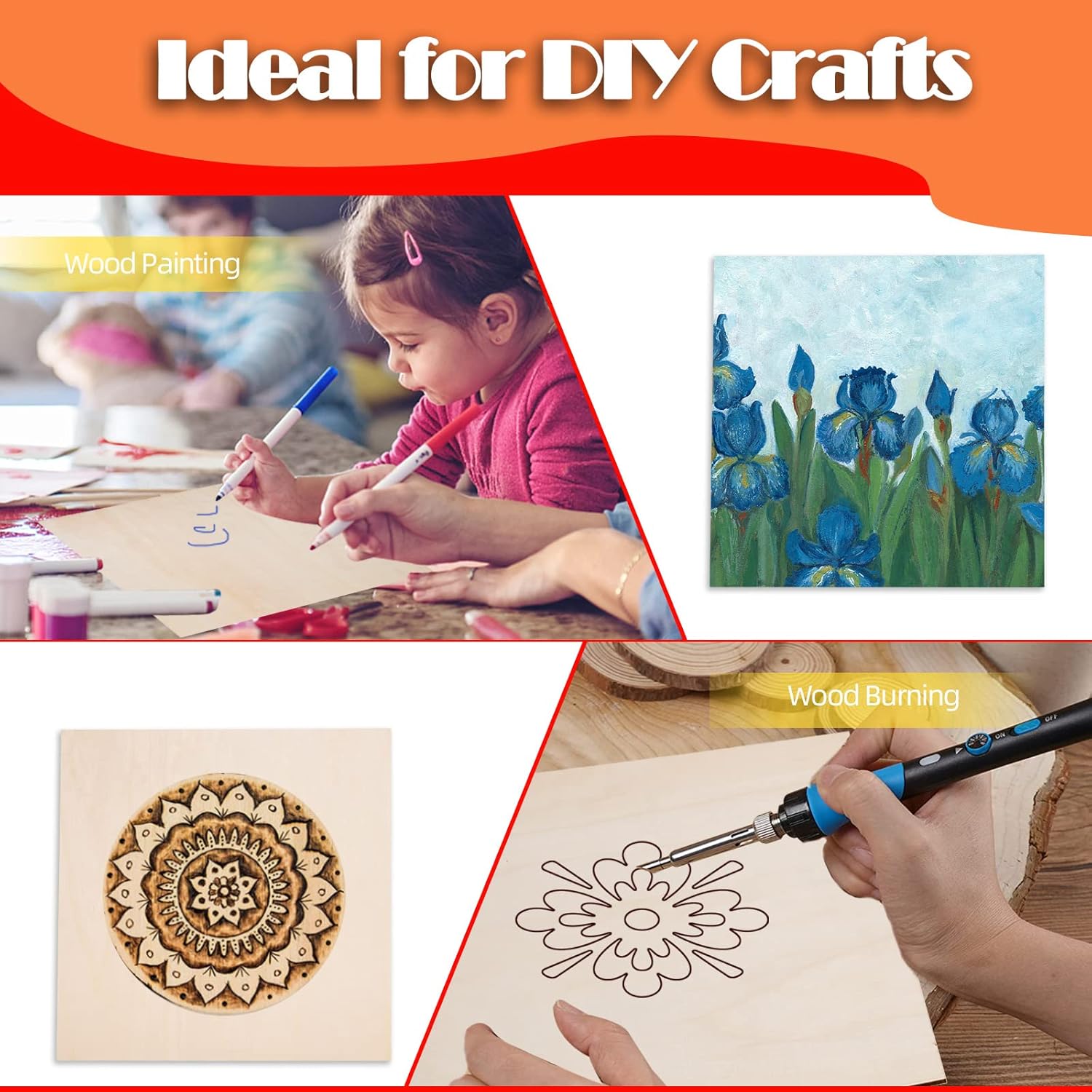

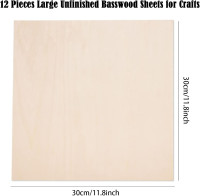

Wholesale 12 Pack Basswood Sheets for Crafts-12 x 12 x 1/8 Inch- 3mm Thick Plywood Sheets with Smooth Surfaces-Unfinished Squares Wood Boards for Laser Cutting, Wood Burning, Architectural Models, Staining 12 x 12 inch

Wholesale 12 Pack Basswood Sheets for Crafts-12 x 12 x 1/8 Inch- 3mm Thick Plywood Sheets with Smooth Surfaces-Unfinished Squares Wood Boards for Laser Cutting, Wood Burning, Architectural Models, Staining 12 x 12 inch

Check product retail prices on Amazon, eBay, Walmart worldwide, see monthly sales volume and marketplace commissions for easy calculation of your potential profit.

Shipping costs are estimates only. Please feel free to place an order to find out the final shipping cost, which may be significantly lower than that displayed.

We can deliver directly to the warehouse of Amazon, Ebay or Walmart, customize the product, as well as print and stick the necessary stickers.

The more you order, the cheaper is shipping. Add 0 kg to get the best shipping rate.

Specify order quantity to calсulate shipping costs.

1. Warping: Several customers have reported that the basswood sheets tend to warp after being cut with a laser. This warping affects the flatness of the material and could potentially impact the quality of the final product.

2. Thickness Variation: Some customers have noted that there is batch-to-batch variation in the thickness of the basswood sheets. This inconsistency can be problematic, especially for projects that rely on standard thickness for precision.

3. Size Concerns: One customer pointed out that the actual width of the sheets is slightly less than the advertised size, which can be an inconvenience for projects that require precise measurements.

Plan for Improvement:

1. Address Warping Issue:

- Investigate the root cause of warping after laser cutting and implement measures to minimize it, such as using a different type of adhesive for the layers.

- Conduct tests with different laser settings to identify optimal cutting parameters that minimize warping.

- Consider implementing a post-cutting treatment method to reduce warping, such as applying heat or pressure to restore flatness.

2. Ensure Thickness Consistency:

- Implement strict quality control measures during manufacturing to ensure that all batches of basswood sheets maintain a consistent thickness.

- Regularly calibrate machinery and equipment used in the manufacturing process to prevent variations in thickness.

- Provide clear labeling on product packaging to indicate batch information, allowing customers to easily identify any thickness variations.

3. Address Size Discrepancies:

- Clearly state the exact measurements of the basswood sheets on the product packaging and online listings to manage customer expectations.

- Conduct regular quality checks on finished products to ensure that they meet the specified size requirements.

- Offer options for custom sizing to accommodate customers who require precise dimensions for their projects.

By implementing these improvements, the manufacturer can address the issues highlighted in customer reviews and enhance the overall quality and customer satisfaction with the basswood sheets for crafts.